Food Safety: Biofilm Testing, Formation, Identification and Removal.

Biofilm testing has become an immensely critical aspect of the modern world as protecting consumers from foodborne illness has become a global challenge for food and dairy producers. The increase in foodborne illness outbreaks raises food safety concerns. Many such outbreaks have been associated with the formation of biofilm by foodborne pathogens.

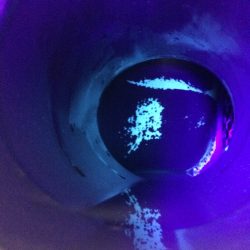

Biofilm and soiling adhesion on a process line internal surface

Biofilm can form just about anywhere in a food processing plant — even the cleanest looking surfaces can be a threat to food safety if an invisible layer of bacteria is present. Why does biofilm form and how can it be prevented? Knowing how to detect and eliminate biofilm is crucial to ensuring your food plant’s processing equipment is contaminant-free and not to adversely affect the safety and quality of the products.

Sources of contamination in food and dairy processing environments can be caused by several various variables, one being is prolonged production runs, insufficient CIP cleaning and poor vessel design leaving biofilm / bio-fouling residues on internal surfaces in finished process tanks, vats, silos, processing vessels, spray dryers, storage vessels and process pipework.

What is a biofilm and why is it dangerous?

Biofilm sounds like something out of a biology textbook, and it is, but it works just like many other substances.

Bacteria thrive in food and dairy processing plants thanks to the moisture and nutrition they produce. When these organic and inorganic compounds mix, they create a “conditioning layer,” which is an environment suited for bacterial growth. As free-floating bacteria multiply, they begin to secrete extracellular polymeric substances (EPS), which helps them stick to any surface and each other to create a film.

Having biofilm form in your plant is a risk to food safety, reduces shelf life and can lead to costly recalls. If biofilms go unchecked, they can adhere to surfaces so firmly that they become resistant to standard sanitization procedures. Since biofilms can be home to strains like listeria, salmonella and E. coli, it’s crucial to prevent their growth.

Where do biofilms grow?

Biofilms can form on all types of surfaces, including plastic, metal, glass, cement and wood. They’re most likely to form on rougher, more porous surfaces or equipment with cracks and scratches.

Because biofilm is made up of microscopic bacteria, it can be hard to detect with the naked eye, especially early in its growth. However, food and dairy processors can be on the lookout for:

- A rainbow-like appearance on stainless steel surfaces;

- A slimy feeling on surfaces that otherwise look clean;

- Sour or off-putting odours.

If food and dairy producers suspect biofilm is forming, there are testing methods and solutions that can confirm its presence.

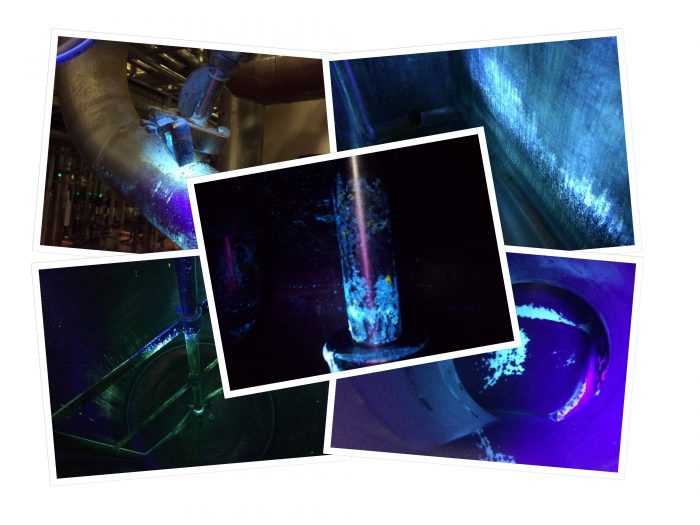

Independent Integrity Inspection Limited has the ability and quick solution for biofilm testing to highlight problematic areas of concern within seconds or minutes compared to other cumbersome and time-consuming alternatives.

Making the invisible – visible using state of the art technology and/or unique non-toxic chemicals combined with highly experienced technicians, a prompt detailed survey of various surfaces, process equipment and pipework can be conducted detailing areas that are not being cleaned properly due to poor CIP design/cleaning which require further hygienic actions to be taken.

The problematic area(s) of concern can be viewed by all concerned parties in “real-time” and further action plans can be formulated to combat the pathogen risk and thus reducing the bacteria contamination and improving the shelf life of the products being produced.

This method of detecting biofilm / bio-fouling residues can form a crucial part of any “Hazard Analysis and Critical Control Points (HACCP)” programme.

Examples of areas susceptible to biofilm formation.

Dead ends, corners, cracks, crevices, gaskets, valves, joints, heat exchangers and tank surfaces are all possible points for biofilm formation.

Established Biofilm and removal.

Once established, biofilms are very hardy communities that require a considerable time and effort to eliminate. Facility and equipment should be hygienically designed so bacteria cannot find harborage sites that protect them from cleaning and disinfection. Additionally, the removal of biofilms is greatly affected by the application of mechanical force, such as brushing and scrubbing, to the surface during cleaning.

Advice and solutions can be provided by our expert team. We can advise and suggest different CIP cleaning activities and solutions to eliminate and promote cleanliness within the production process line.

Please contact us to find out more about the services we offer or fill in the online enquiry form here:

Heat Exchanger / Pasteuriser Testing – click here

Tank, Silo, VAT and Vessel Testing – click here

Spray Dryers, Cyclones and Fluid Bed Testing – click here